Electricity network operators are required by the Energy Industry Act to ensure the security and reliability of the electricity supply in their network.

Redispatch refers to interventions in the generation output of power plants in order to protect line sections of the electricity network from overload and avoid bottlenecks. If there is a threat of congestion, certain power plants are instructed to reduce their feed-in capacity. At the same time, other power plants must increase their feed-in capacity. This balance-neutral control creates a load flow that counteracts the bottleneck.

Due to the steady growth of renewable energies, whose feed-in capacity is also largely determined by the weather and is subject to strong fluctuations during the course of the day, grid operators have to carry out redispatch measures more and more frequently.

Previously, redispatch was only carried out with conventional large-scale power plants of 10 MW or more.

With the new Redispatch 2.0, all generation plants with a generation capacity of 100 kW or more, as well as smaller plants that can already be remotely controlled by the grid operator, will also be included in this control process on a mandatory basis. This also includes many decentralized CHP, wind and photovoltaic plants.

The aim is to increasingly use even more accurate forecast data for predictive grid control in order to ensure grid stability and avoid bottlenecks. In addition, decentralized EEG plants are often located closer to the bottleneck to be resolved and can therefore be deployed in a more targeted manner. This reduces the control services required from large power plants and helps to lower costs in the overall system.

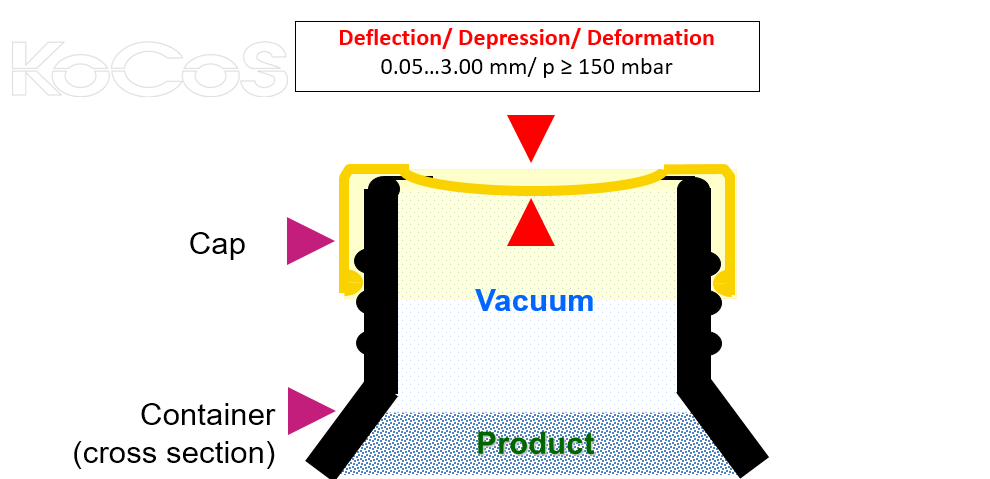

When Redispatch 2.0 comes into force on 01.10.2021, operators of affected generation plants will be obliged to regularly provide comprehensive data to the grid operator. This includes, among other things, the live measurement data of the plant, which the grid operator can use to determine the power reserve available to it on the basis of the average power value of the past 15 minutes and use it for redispatch. This data is also used to determine possible compensation payments.

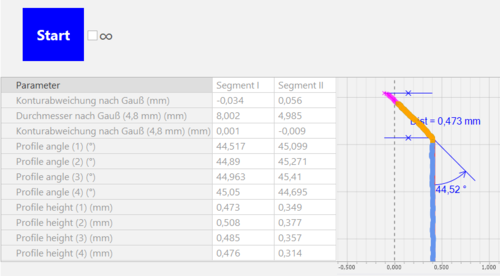

But it is not only the power data that is of interest here. The applicable technical connection rules for power generation plants in medium and high-voltage networks VDE-AR-N 4110 and VDE-AR-N 4120 additionally prescribe the monitoring of voltage quality according to EN 50160 Class A as well as the high-resolution recording of network disturbances.

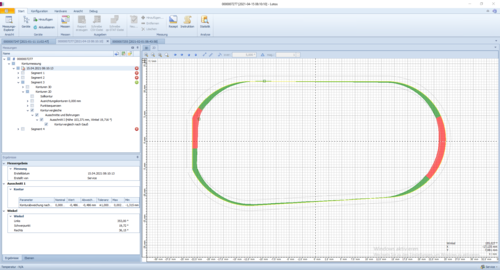

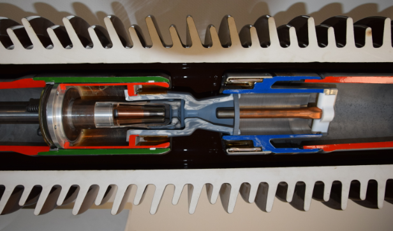

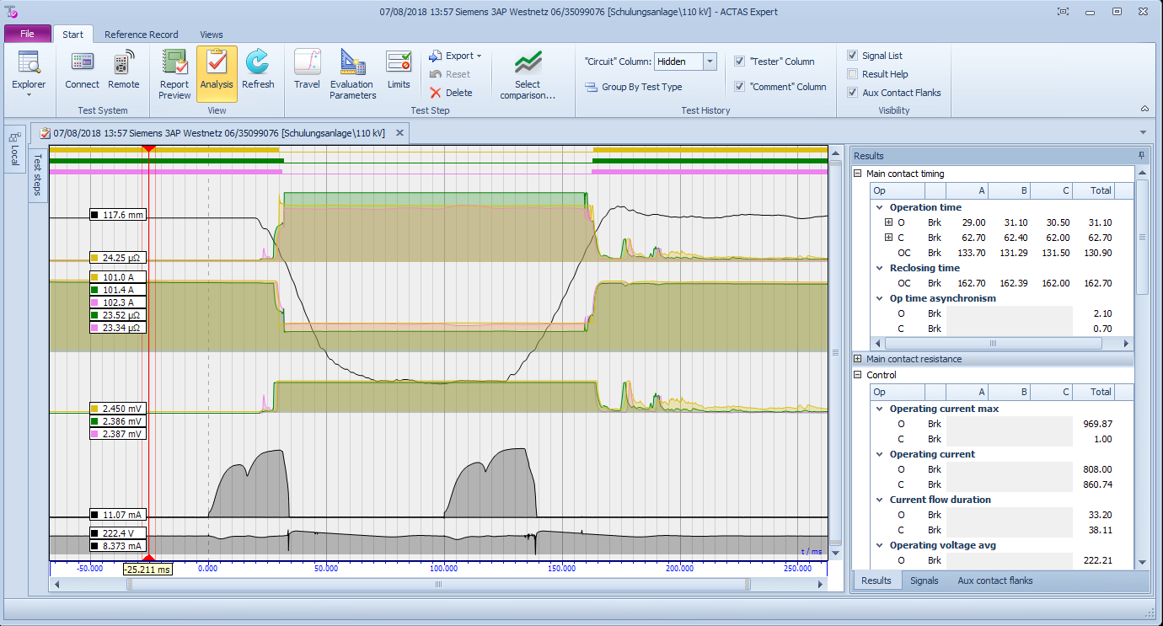

The measuring systems of the EPPE and SHERLOG product lines fully meet the requirements. Permanent power quality measurements, transient disturbance recordings as well as real-time measurement data transmission and visualization are performed in parallel and independently on these systems.

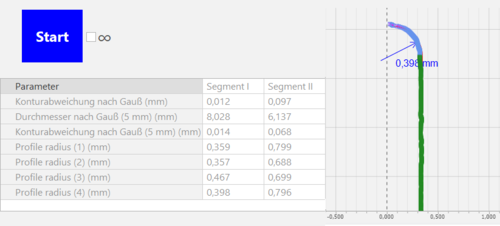

Voltages and currents are recorded with a temporal resolution of 200 kHz and a measurement deviation of maximum 0.05%. The resulting data is stored fail-safe in a 32 GB ring buffer and transmitted via cable or LTE/G5-based network connection or can be read out directly at the device via USB interface. The remote data transmission can be time or event controlled. Thus, for example, a detailed fault report including the fault type, fault duration, maximum values that occurred, fault impedance and fault location can be automatically generated by the associated Expert software just a few seconds after a fault occurs and sent to operations management, e.g. by e-mail. Voltage quality reports can also be generated automatically and stored as PDF reports. Real-time measurement data can be read out via MODBUS or IEC 61850, for example, and visualized on all common browsers and platforms via the integrated web server.