The importance of testing earth ground connections

05. October 2022, - Resistance measurement

By:

Brian Burke, Application Engineer, KoCoS America LLC

Guy Wasfy, Managing Director, KoCoS America LLC

Jürgen Dreier, Product Manager, KoCoS Messtechnik AG

Bonding connections and ground connections are an essential component for the safe functioning of power and communications engineering systems and for ensuring personal and equipment safety.

Unwanted voltage potential differences are to be avoided by means of ground connections and grounding procedures. These voltage potential differences can occur between metallic components and ground, which can endanger human safety and/or technical equipment.

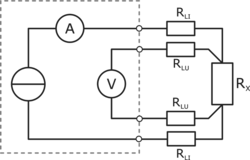

Metallic components must be connected to ground potential to prevent dangerous voltages. Voltage drops are reduced by grounding all non-voltage-carrying parts and by extensive ground potential equalization (grounding system). It is important to make sure these grounding connections have a low resistance. Resistance measurements must be made at both potential and ground connections to ensure that a sufficiently good low resistance connection is achieved and maintained.

Below is an example of application in power distribution where grounding and equipotential bonding and their good connection are important. However, there are many other applications where grounding and equipotential bonding must be taken into account (Rail vehicles, aviation industry and aircraft maintenance, etc.). Typical applications for equipotential bonding and grounding are found in power distribution substations in low and medium voltage networks and especially in high voltage substations. The grounding of all non-voltage-carrying parts and extensive ground potential equalization reduce voltage drops that can occur due to capacitive or even inductive voltage coupling.

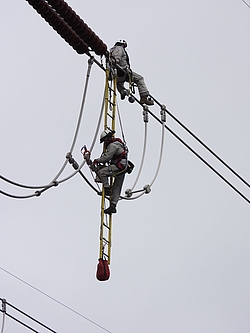

An example of these non-voltage-carrying parts is the mechanical disconnect switches used to remove a switchgear from service. Due to the need for human interaction with these physical switches, it is critical their grounding connection is not compromised. These straps are metallic braids secured via bolts to the switch and ground connection point. These straps can become poor conductors due to corrosion or physical damage. A compromised strap could lead to improper grounding of the switch causing a hazardous touch potential when the switch is to be used. To ensure the straps are functioning accordingly, the connection across them can be tested with a micro-ohm measurement. A failing strap will have a high resistance reading where as a properly conducting strap will have a low resistance reading. High resistance of the connection or, in the worst case, a failing strap could require the bolted connection points being cleaned and reconnected or the strap being replaced entirely.

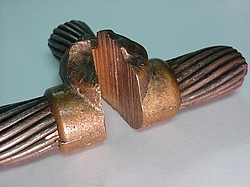

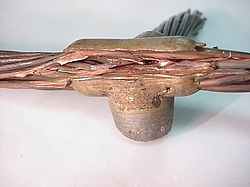

Aside from bolted ground straps, the grounding connections can be bonded through exothermic welds. These welds result in superior mechanical and electrical bonding. Especially for conjoining dissimilar metals, such as joining a copper grounding rod to a galvanized metallic structure in a substation. These welds, when done properly, create a solid and reliable connection (Figure 2) Due to improper heating or unwanted moisture, the welds can have pitting or gaps (Figure 3) and be considered poor quality both mechanically and electrically. Performing a micro-ohm resistance measurement across these connections can give insight into the weld quality. The more solid the weld connection is, the lower the resistance reading will be. A poor quality weld could result in a less reliable grounding connection.

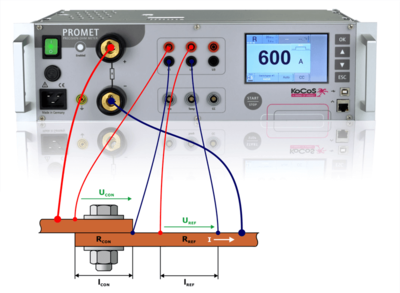

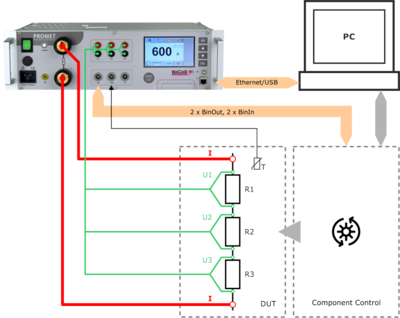

The resistance measuring instruments from KoCoS Messtechnik AG are ideal for measuring equipotential bonding and earth connections. The PROMET SE precision resistance measuring instrument is used to determine low-resistance in the μΩ and mΩ range. With adjustable test currents of up to 200 A, in conjunction with a four-wire measurement method, the systems provide measurement results for the highest accuracy requirements. The use of state-of-the-art power electronics and the robust design guarantee maximum reliability for mobile use.

The PROMET SE is ideal because it is battery operated and does not require a mains connection. Some of the connections described may be at height so that the tester is standing on a ladder or similar. Without the battery operation, the meter would also require a portable generator. Finally, the PROMET SE is very lightweight and easy to transport. It weighs less than 5 pounds and can be conveniently transported on-site to test the many ground connections.

If you have questions or additions to the resistance measurement or to our measuring devices? Then contact us via the comment function here on the blog or by mail to info(at)kocos.com.