Vacuum inspection as factory insurance

25. January 2021, - Vacuum inspection

Ensuring the highest product quality is a primary and indispensable goal, especially in food production. One of the standardized methods for preserving food without the addition of preservatives is vacuum packaging. By reliably lowering the oxygen partial pressure inside the container, the growth of spoilage germs is suppressed and thus the minimum shelf life of these foodstuffs is significantly extended. However, if the vacuum packaging is not absolutely flawless and has leaks, food can spoil long before the stated expiry date.

Vacuum inspection for bottles, jars and cans

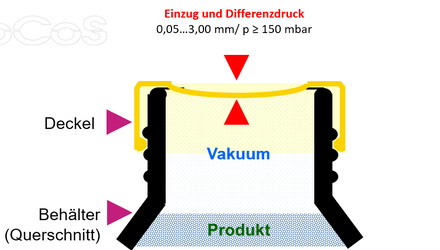

The test procedure is based on determining the vacuum-induced deformation of the container closures as they pass through. The tightness of the containers is assessed by comparison with a previously Golden sample. Depending on the existing basic conditions, vacuum tests are possible from 50 µm deformation or from 150 mbar differential pressure in the headspace to the external pressure.

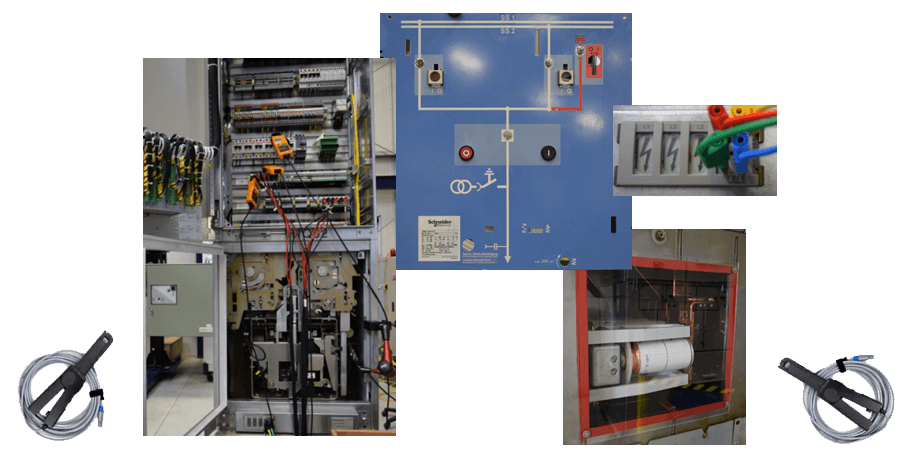

The INDEC systems work with an optical infrared sensor head. This means that metallic and non-metallic closures can be inspected equally. Starting with flow-rates of up to 600 pieces/min in the basic model, up to 1,200 pieces/min are achieved in the highest expansion stage for cap sizes of 30...110 mm diameter.

Convincing advantages through optical measuring method

The optical measuring method of the INDEC model series has a number of satisfying advantages compared to conventional methods. Due to the large working distance of the sensor head of more than 100 mm, the system is able to fully tolerate a wide range of deviations caused by dimensional deviations of the containers, horizontal track misalignment of the test samples and the unavoi-dable inaccuracies in the manual height adjustment of the sensor head.

Even vibrations of the conveyor belt and occasional drops of water on the caps do not affect the correct operation of the INDEC system, in contrast to other measuring methods.

INDEC the business insurance

Complaints, image damages, loss of customers and high costs are possible consequences of leaking vacuum packaging. The consequences can be serious, especially for the existence of small and medium-sized companies. The use of appropriate vacuum inspection systems should therefore be a matter of course wherever vacuum packaging is produced.

Unfortunately, the consistent use of effective inspection systems in companies that fill food is not a matter of course. During our on-site visits, we repeatedly see production facilities where no such inspection technology is used. The INDEC inspection devices are easy to integrate into existing plants and offer the possibility of updating existing measuring technology to a modern standard at low costs. As a complete installation, the turnkey INDEC test systems offer an "all-round carefree package" with which reliable quality assurance can be achieved quickly and easily.