Differences between AIS and GIS testing

18. November 2020, - Circuit breaker testing

Timing measurements of AIS and GIS switchgear, what are the differences?

GIS high-voltage switchgears are located at many nodes in our voltage network, such as three-phase or single-phase encapsulated switchgear panels. High-voltage switchgears consist of several components and can be designed differently depending on the required function. They contain components such as current transformers, disconnectors, ground switches, circuit breakers, etc. Compared to air insulated switchgear (AIS), they offer a number of advantages, including smaller space requirement, higher personnel safety, a longer service life, and higher reliability. Disadvantages compared to AIS are evident in terms of maintenance, as individual components are very difficult to access. Measurements, such as those of circuit-breaker operating times and resistance of the circuit-breaker interrupter units, are rather difficult to carry out, since the basic requirement is that in high-voltage installations, all the parts being worked on must be grounded.

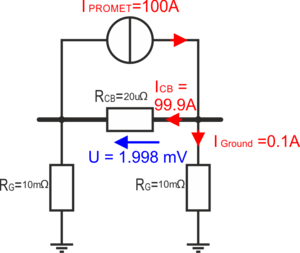

In outdoor switchgear systems (AIS), measurement with ground on both sides is generally not a major problem, simply because the typical ground resistance is much higher than the main contact resistance. KoCoS uses "Dynamic Timing" to combine the ACTAS switchgear test system with PROMET resistance meters.

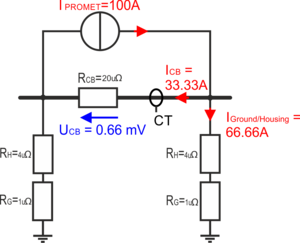

The standards DIN VDE0105-100 and EN50110-1 clearly state that a GIS system must be measured with ground on both sides. The problem, which is particularly relevant for GIS, is the very low ground resistance resulting from the encapsulation of the entire switchgear in a metal housing. It often can be that the ground and housing resistance is lower than the main contact resistance. This makes it difficult to carry out a condition assessment of the switchgear using standard measuring equipment.