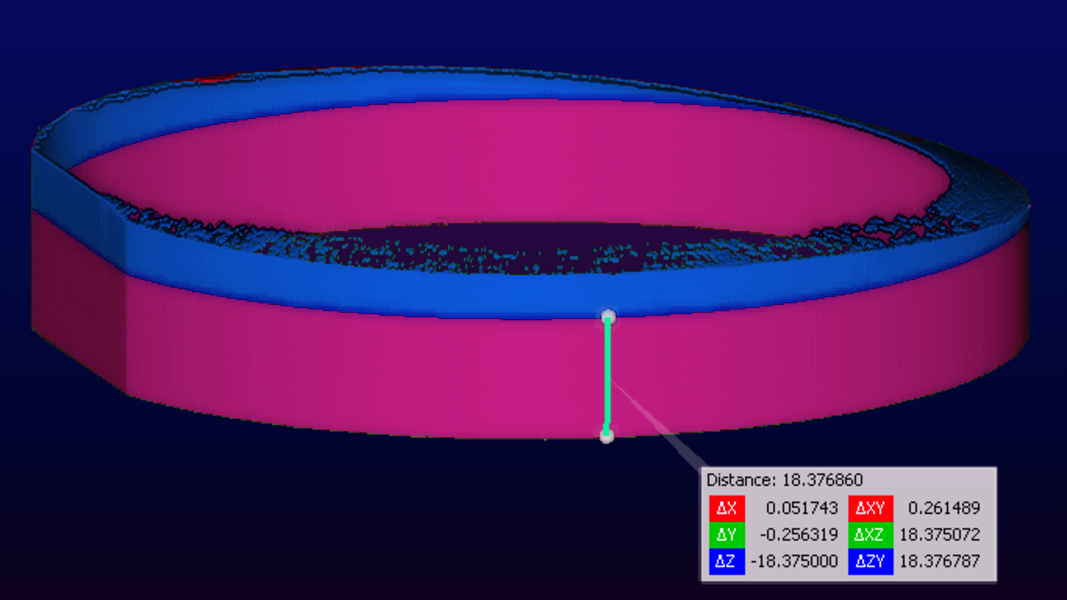

LOTOS automatic measuring systems can measure the full outer and inner contours or individual areas of any measurement object quickly and precisely, irrespective of the shape, and test them for defects. The three-dimensional, non-contact measurement is carried out using optical measurement sensors with accuracy in the μm range.

LOTOS automatic measuring systems can measure the full outer and inner contours or individual areas of any measurement object quickly and precisely, irrespective of the shape, and test them for defects. The three-dimensional, non-contact measurement is carried out using optical measurement sensors with accuracy in the μm range.

The result is a representation of the measurement object as a 3D model. Powerful, intuitive software allows the measurement results to be assessed extremely quickly.

Can be equipped with various measuring sensors and actuators to achieve the highest measuring rates in the second cycle up to the highest measuring accuracy in the sub-micrometer range. Measuring speeds from 4 seconds per component with measuring ranges from 0mm to 750mm configurable for a wide range of test part dimensions.

... here we go

The inspection systems of the LOTOS product range have been specially developed to perform various 3D measurements and inspections. Here you can find application reports and application experiences.

... here we go

Extremely fast measurements every second!

Extensive product line with solutions for every requirement profile.

Very flexible in use, thanks to adaptable measuring range.

Robust and reliable for direct use in the production environment.

Data and control interfaces for all "Industry 4.0" or IIoT requirements.

The KoCoS devices convince with performance and reliability!

Free software with incredibly wide-ranging evaluation functions.

Real-time monitoring of the production process.

LOTOS 3D Measuring Systems

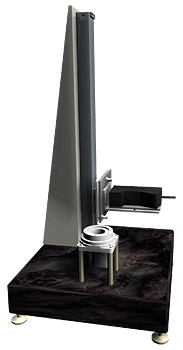

Extremely robust stand-alone system with integrated operation touch screen and a high-performance evaluation unit for maximum measuring and evaluation speeds.

The ergonomic design makes the system extremely service-friendly and easy to maintain. In addition, LOTOS LS measuring systems offer a wide range of connection options and can thus be quickly and easily expanded with peripherals such as code readers.

Extremely robust stand-alone system optimized for inline measurements with integrated operator touch screen and a high-performance evaluation unit for maximum measurement and evaluation speeds.

The design is optimized for integration into the manufacturing process and is therefore particularly suitable for in-process 100% inline inspections. Extremely flexible test part loading via robot or by gantry is ensured by the generous free space above and around the measuring table.

Very flexible and cost-effective standard measuring system.

The stand-alone systems have a height-adjustable operating touch screen and an integrated evaluation unit. The systems are suitable for use in a production environment as well as in a laboratory or measuring room.

Open measuring station, ideal for use in the laboratory and measuring room, as well as in clean manufacturing environments.

It can be configured extremely flexibly to the corresponding requirements for accuracy, measuring speeds and the evaluation options. In addition, the LOTOS O systems are very cost-effective and economical.

Get your free demo and free feasibility studies for your measuring task!

Get your free demo and free feasibility studies for your measuring task!

LOTOS 3D measuring systems - Suitable solutions for every requirement profile

Can be equipped with various measuring sensors and actuators to achieve:

Highest measuring rates at second intervals up to highest measuring accuracy in the sub-micrometer range. Measuring rates from 4 seconds per part with measuring ranges from 0 mm to 400 mm can be configured for a wide range of part dimensions.

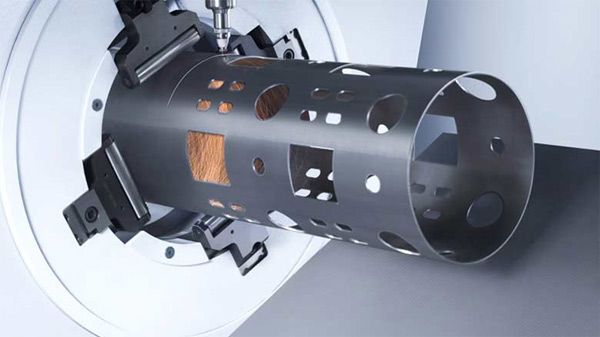

The automatic measuring systems LOTOS are used for the precise determination of geometries at any measuring objects, irrespective of their shape. The measurement is performed by moving optical sensors along the outer contours of the measuring objects. Due to the extremely high sampling rate, both two- and three-dimensional measurements including the evaluation of the results are possible in the shortest time.

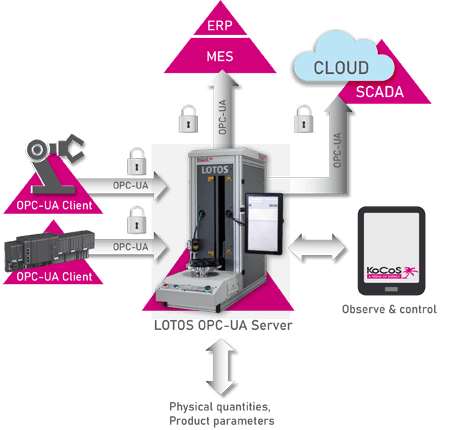

The IIoT (Industrial Internet of Things) capability allows easy integration into state-of-the-art data and control environments and fulfills all the requirements for Industry 4.0.

The powerful software offers a wide range of options for quality assurance, production monitoring and control, as well as technological preparation of new manufacturing processes.

Check geometry quickly and precisely

The test object is rotated on a turntable for scanning, while the optical sensors are moved along the test object by means of a vertical precision measuring axis. The geometry can then be checked fully automatically for predefined properties. Due to the wide range of possible uses, there are applications for in-process testing and for quality inspection in almost all industries.

Cost-efficient due to wide range of possible applications

Thanks to flexible part fixtures and the high variability of measuring ranges, the systems enable the measurement of smallest parts up to heavy machine components. Whether required for tasks connected with development and optimization, or for in-process testing and process control, a wide variety of measuring tasks can be carried out flexibly and efficiently with just one LOTOS measuring system.

High operational reliability and availability

Whether used in the measuring room or in harsh manufacturing environments, the robust design of LOTOS measuring systems guarantees a long service life, while maintenance-free components from leading manufacturers ensure high reliability. The entire mechanics and sensor technology is dust-protected and designed to compensate for environmental influences. In addition, self-monitoring functions provide high operational reliability and accuracy even under fluctuating environmental conditions.

Equipped to meet all Industry 4.0 requirements

The comprehensive software package makes these measuring and test systems suitable for use in the areas of development and application, as well as for 100% in-line testing. All LOTOS models are futureproof and feature interfaces for stand-alone use, or for partially or fully automatic operation within the production environment. As a result, the measuring systems are well equipped to meet upcoming Industry 4.0 requirements.

Shape and position tolerances according to ISO 1101 for the entire test object, freely definable sections or individual areas can be measured:

Identification of imperfection

Geometric measurements

Shape and position testing

Industry 4.0 and Industrial Internet of Things

LOTOS measuring systems as OPC-UA server

The central challenges of Industry 4.0 or the Industrial Internet of Things (IIoT) are security and a standardized exchange of data and information between machines, devices and services from a wide range of industries. LOTOS measuring systems as OPC-UA servers help to meet the high demands on industrial networks and to implement a standardized, secure exchange of information.

KoCoS Downloads

Here you can find detailed information on our devices and applications, as well as brochures, application reports, technical details, technical papers and much more.

KoCoS customers can also log in with a user name and password to access an even wider range of information. Enjoy browsing and reading!

Downloads

Application Report

LOTOS - Industrial Digitalisation

1 MB

Application report

LOTOS gear measurement

460 KB

Blogs

LOTOS Blog Posts

Blog posts with interesting and practical background information about LOTOS 3D Measurement and Inspection. Here you will also find answers to practical questions on specific topics about measuring and inspection technology and its applications.

Just take a look and find out more!

... here we go

Contact

Whatever your request, we‘re here for you.

Whatever your request, we are here for you! Just enter contact details and the subject of your request and we will be happy to get back to you personally.

Or e-mail to: info(at)kocos.com

Contact ![]()

Let‘s stay in touch!

Subscribe to the KoCoS newsletter and be the first to know about our products, updates and other news.

Subscribe ![]()

Whatever your request, we‘re here for you.

Whatever your request, we are here for you! Just enter contact details and the subject of your request and we will be happy to get back to you personally.

Or e-mail to: info(at)kocos.com

Contact ![]()

Let‘s stay in touch!

Subscribe to the KoCoS newsletter and be the first to know about our products, updates and other news.

Subscribe ![]()