The wafer edge profiler WATOM from KoCoS sets the worldwide benchmark for the quality assurance and process control of edge grinding and polishing process combining the highest quality standards with top-class service.

The wafer edge profiler WATOM from KoCoS sets the worldwide benchmark for the quality assurance and process control of edge grinding and polishing process combining the highest quality standards with top-class service.

The patent laser technology measures the edge profile not only on any point of the circumference even so inside the notch. Leading wafer manufacturer across the world use WATOM as their state-of–the art tool for geometrical measurement of wafer edge.

WATOM LS is your choice to control your wafer edge profile grinding process for a broad range of substrate types and sizes including silicon, silicon carbide, gallium arsenide, germanium glass, sapphire and others.

... read more

WATOM CCD is your choice to control your wafer edge profile polishing process for a broad range of substrate types and sizes including silicon, silicon carbide, gallium arsenide, germanium, glass, sapphire and others.

... read more

WATOM T is your choice for wafer edge profile measurement for low volume and cost saving solutions.

The space-saving table-top tool for integration in small productions and for sample test requirements.

... read more

WATOM LS

WATOM LS

Wafer Edge Measurement - pinpoint precise

The use of smaller and smaller patterns in the semiconductor industry calls for increasingly advanced materials of extremely high quality. In response to the steady improvements in the quality of wafers, KoCoS Optical Measurement has developed WATOM, a wafer edge and notch profile measurement tool which heralds a new era of extremely precise wafer geometry measurement.

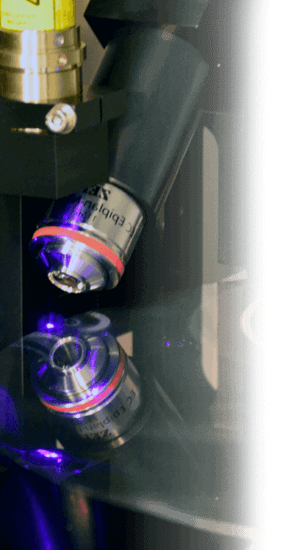

The patented measurement method of WATOM LS utilizes a lightsectioning sensor to measure the profile of the wafer edge with pinpoint precision, including the profile within the notch. Using a CMOS camera, pictures are taken of the laser line produced by the edge profile. A mathematical algorithm developed by KoCoS is then used to determine the edge profile characteristics.

The modular design of WATOM is prepared to be combined with various automation solutions for modern semiconductor manufacturing processes, whether individual wafers are loaded manually or an automated material handling system (AMHS) is in place.

...read more

WATOM CCD uses profile projection technology as an alternative to the LS technology and provides the ideal solution for less demanding profile measurement requirements, in particular when notch measurement is not required. A CMOS camera captures the profile image of the wafer edge illuminated by a telecentric light source.

The modular design of WATOM is prepared to be combined with various automation solutions for modern semiconductor manufacturing processes, whether individual wafers are loaded manually or an automated material handling system (AMHS) is in place.

...read more

WATOM T

Small footprint and consistent accuracy

WATOM T is a compact, inexpensive alternative for applications that have no automation requirements and provides the same quality, process reliability and measurement precision as other WATOM systems.

WATOM T is designed to accept two wafer sizes for quick sample measurement.

Equipped with a touch screen, this tool is easy to use for operators, experts and maintenance staff alike.

...read more

Contact

Whatever your request, we‘re here for you.

Whatever your request, we are here for you! Just enter contact details and the subject of your request and we will be happy to get back to you personally.

Or e-mail to: info(at)kocos.com

Contact ![]()

Let‘s stay in touch!

Subscribe to the KoCoS newsletter and be the first to know about our products, updates and other news.

Subscribe ![]()

Whatever your request, we‘re here for you.

Whatever your request, we are here for you! Just enter contact details and the subject of your request and we will be happy to get back to you personally.

Or e-mail to: info(at)kocos.com

Contact ![]()

Let‘s stay in touch!

Subscribe to the KoCoS newsletter and be the first to know about our products, updates and other news.

Subscribe ![]()