Use of KoCoS micro-ohmmeters to optimize electrical connections

14. February 2024, - Resistance measurement

In our latest blog, we provide exciting insights into the use of our PROMET R600 micro-ohmmeter at the renowned company TRUMPF Laser-und Systemtechnik GmbH. Read how our micro-ohmmeter helps to minimize electrical losses and thus also ensures longer ranges for electric vehicles.

The requirement: Reduction of contact resistances

In e-mobility, systems and components must be one thing above all else: extremely efficient. Every kilometer counts and vehicles with a long range have the edge. Even the smallest components often have a major influence on this - such as copper contacts. These so-called busbars are often used in inverters and conduct the current from the battery to the drive, for example. They are usually screwed together. However, this reduces conductivity: a lot of energy is transferred via the contacts. The force-fit connection using a screw leads to a high contact resistance and therefore to power losses. To make matters worse, although copper is very conductive, it oxidizes quickly. The oxide layer on the surface also causes energy losses at the connection points. In electric vehicles, this affects the range, reduces performance and shortens the service life of the components. Reducing the contact resistance of billions of connections in e-vehicles worldwide offers enormous savings potential here.

The solution: Structuring the joint with a laser

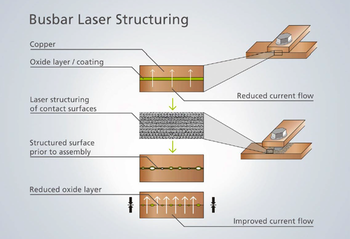

TRUMPF takes this into account with a specially developed laser process. With its TruMicro7070 lasers, the Ditzingen-based company structures the copper busbars at the connection point before screwing them together. The laser removes any impurities and the old oxide layer and also creates a specific surface topography. The resulting new, pure oxide layer protects and preserves the condition of the surface in the long term. During screwing, the resulting structure leads to micro-deformations, resulting in a significant reduction in electrical losses - even over several screwing and unscrewing cycles.

The laser removes the old oxide layer from the copper surface and ensures better conductivity at the screwed points thanks to the structuring.

The proof: measurement with the PROMET R600 micro-ohmmeter

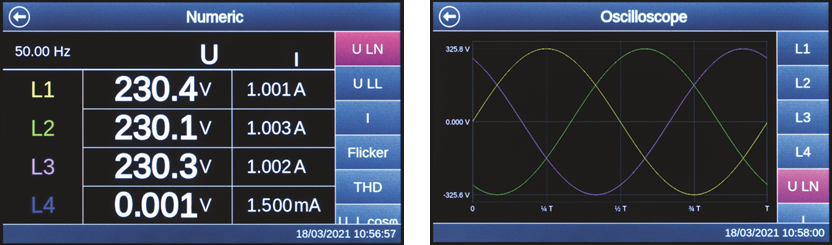

The electrical conductivity can be determined by measuring the contact resistance. A lower resistance in the contact leads to lower electrical losses in the system and therefore also to a longer service life of the contact.

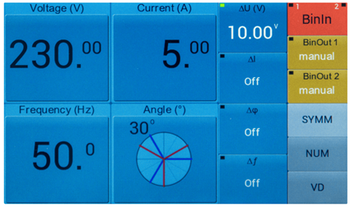

TRUMPF uses our high-precision micro-ohmmeter PROMET R600 for this measurement.

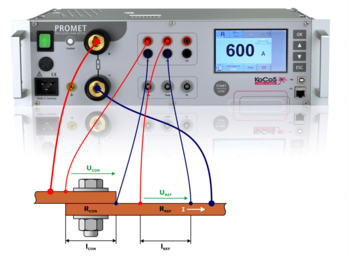

The PROMET R600 is a precision measuring device for determining resistances in the μΩ to mΩ range. Due to the measurement in four-wire technology and the output of high test currents up to 600 ADC, the resistance measuring device meets the highest accuracy requirements. The use of state-of-the-art power electronics and the robust design guarantee maximum reliability for stationary and mobile use in industrial environments such as at TRUMPF.

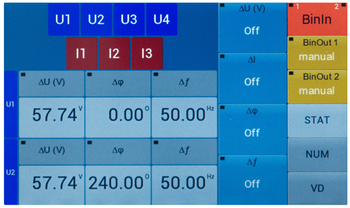

The contacts are evaluated both on the basis of the absolute measurement of the contact resistance and by measuring the so-called quality factor. The resistance in the contact is compared with the resistance in the homogeneous conductor.

By equipping the systems with three voltage measurement inputs, the resistances can be determined and compared in parallel at two measuring points at the same time. The quality factor K is calculated as the ratio of the resistance RCON of the connection over the overlap length lCON to the resistance RREF of the busbar of the same length lREF.

The result allows a direct comparison of different qualities of electrical transitions.

Conclusion

Copper contacts can be structured quickly and efficiently using laser technology. The result is a significantly reduced contact resistance, which is activated when the two metal components are screwed together. The KoCoS precision resistance meters PROMET R300/R600 are an ideal tool for characterizing such connections for high current and low resistance due to their measurement in four-wire technology and the ability to accurately measure both current and voltage.

Information on Trumpf's laser process can be found in the white paper "Laser structuring of copper busbars" at https://www.trumpf.com/de_DE/loesungen/branchen/automobil/e-mobility/laserschweissen-von-leistungselektronik/

Do you have any questions or additions regarding resistance measurement or our measuring devices? Then contact us via the comment function here in the blog or by email to info(at)kocos.com.