Switchgear devices are important components in electricity supply systems. They are developed, constructed and manufactured to work correctly under a multitude of conditions. For this reason, it is necessary to check their performance during construction, manufacture, maintenance and repair.

In electrical energy transmission and distribution systems, switchgear devices are the connection to further parts of an installation. Throughout their operational lives, switchgear devices must constantly be able to connect, interrupt or disconnect operating parts. In the "open" status, they are a puncture-proof disconnection point, in the "closed" status, they carry and control short-circuit currents.

Switchgear devices must survive mechanical and thermal stresses during operation without damage. Friction and abrasion influence the performance of the mechanical parts. The contact systems in the current-carrying circuits can deteriorate and thus increase the development of excessive heat.

In order to guarantee the operation of a switchgear device, the devices must be checked and maintained regularly.

When disconnecting the contacts in a high-voltage circuit breaker, a high-energy switch arc is created. It is necessary for circuit breakers to be able to extinguish short-circuit current arcs within a fraction of a second. For this purpose, circuit breakers feature extinction systems or extinction chambers.

The arc is created after disconnecting the switching contacts. Increasing pressure and flow in the extinction medium concerned cool the arc until it is finally interrupted. When the arc is extinguished, it is necessary for the contacts to move away from each other so that the insulating stroke is reached and no further striking of the arc occurs.

The arc contact establishes the first contact during the closing operation and has the last contact touch during the opening operation. The contacts wear during normal switching operations and also when short-circuit currents are interrupted. If the contacts are in poor condition, the circuit breaker becomes unreliable.

A high contact resistance within a switchgear device leads to high power loss coupled with thermal stress and possible serious damage to the switchgear device. Problems, such as high transfer resistance resulting from poor connections, can be identified by measuring contact resistance.

Regular measurements of the static and dynamic contact resistance allow an accurate assessment of the condition of the entire contact system. This ensures that maintenance requirements can be identified at an early stage and down times kept to a minimum.

For the static resistance measurement, the contact resistance is determined when the interrupter unit is closed. However, this measurement does not give an indication of the internal state, especially of the arc contacts.

An assessment can be made by an internal inspection of the contact, but it is very labour-intensive and time-consuming. To simplify analyses of circuit breakers, the dynamic resistance measurement was introduced.

The contact resistance is dynamically measured via an close-open operation. The contact characteristic and the arc contact can be reliably determined via the measurement results.

During this switching operation a high test current is applied and the voltage drop is measured. The measurement of the complete switching operation shows the resistance characteristic of the entire contact travel.

The information given by the dynamic resistance measurement provides an overview of the entire contact status, particularly the arc contact and the eroded parts, which is not possible with the static measurement.

The screen shot shows the characteristic of the dynamic resistance measurement. The characteristic shows the movement of the contacts. The transition to the arc contact is clearly visible. If the travel is measured, the length of the arc can also be determined. The display of the resistance characteristic and the length of the arc contact provides an insight into the internal status of the contact without having to open it.

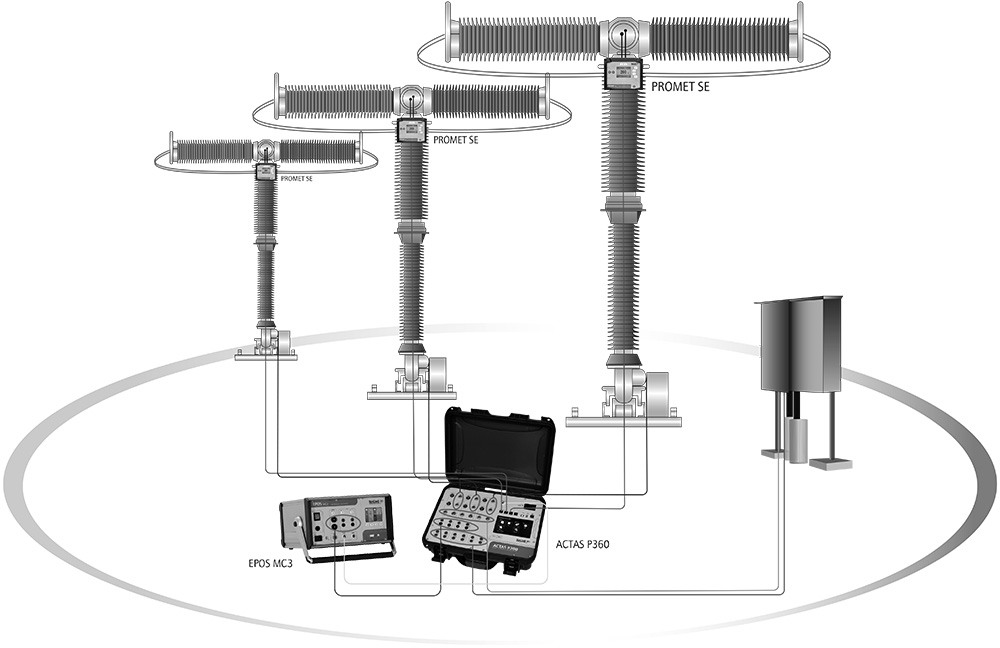

Contact resistance measurements can be carried out with the KoCoS PROMET SE ohm meter and can be incorporated within the test procedure. The test current can be set to a maximum of 200 A. Even very low resistance values in the single-digit micro-ohm range can be measured extremely accurately. The measured values are used for the evaluation of tests and are included in the test report.

When used in combination with ACTAS, PROMET SE can carry out dynamic contact resistance measurements on three poles and on two interrupter units per pole simultaneously. This means that the measurement can be carried out on all the contacts of a switchgear device in a single operation. This eliminates time-consuming connection and disconnection procedures and ensures that the measurement is carried out under identical conditions, allowing direct comparison of the contact resistances with one another.

Switchgear equipment should be earthed on both sides when people are in the vicinity in order to prevent danger caused by capacitively coupled voltages from neighbouring components. However, when switchgear equipment is tested using conventional measuring methods, earthing must be removed on at least one side.

With the dynamic resistance measurement method, measurements can be carried out with earthing on both sides. Not only does this make tests much safer, it also makes them simpler and quicker because all the steps which need to be taken in order to remove the earth lead are no longer required.