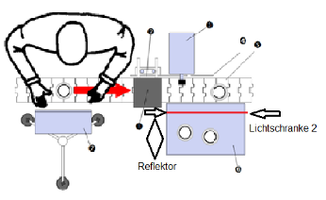

The new large display unit for INDEC 300 vacuum inspection device

10. septiembre 2021, - Vacuum inspection

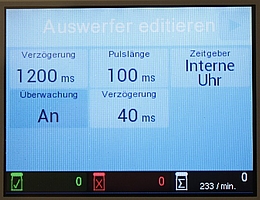

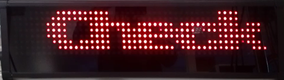

Recently, customers have repeatedly asked us about a suitable large display unit for INDEC systems. They would like to be informed about the current degree of processing for the current batch as well as about error messages on a large-format display, which is visible from afar in the production hall. We are pleased to announce the availability of such a large display with an edge length of 63 x 14 cm for INDEC 300 model.

As you can see in the photos below, the counter number as well as the error messages are easily readable from a great distance. This makes it possible for the operating personnel to quickly take the necessary precautions to immediately eliminate the deficiencies in the filling process.

https://cloud.kocos.com/index.php/s/rG6n38xkPzwo7CA

As a rule, the vacuum testing system is not constantly monitored by the operating personnel. If, during the 100 % inspection of all containers, a system error of the filling line or an equipment malfunction of the INDEC system should occur, this shop floor result display immediately informs the system operator.

Gerald Herrmann

product manager