Signalling operational readiness

-

07. marca 2022

-

Vacuum inspection

-

07. marca 2022

-

Vacuum inspection

Electrical switching contact for signalling the operational readiness of INDEC VD 100 vacuum inspection device

With our INDEC series vacuum inspection systems, food manufacturers have the certainty that the HACCP principles (Hazard Analysis & Critical Control Points) are fulfilled.

In the past, we have been asked several times by our customers whether INDEC VD 100 inspection system can provide a signal to the higher-level machine control which signals that the measuring system is ready for operation. This electrical switching contact for signalling the switch-on state of INDEC VD 100 system is now also available as a retrofit option for already supplied INDEC systems.

After pressing the main switch on the front panel, the INDEC VD 100 vacuum device is switched on. A visual check of the device by the user ensures that the vacuum tester is ready for operation, the relevant recipe has been loaded and all distances for the sensor head and the light barrier have been set correctly. The readiness for operation of the INDEC VD 100 is signalled to the higher-level machine control system by an electrical switching contact.

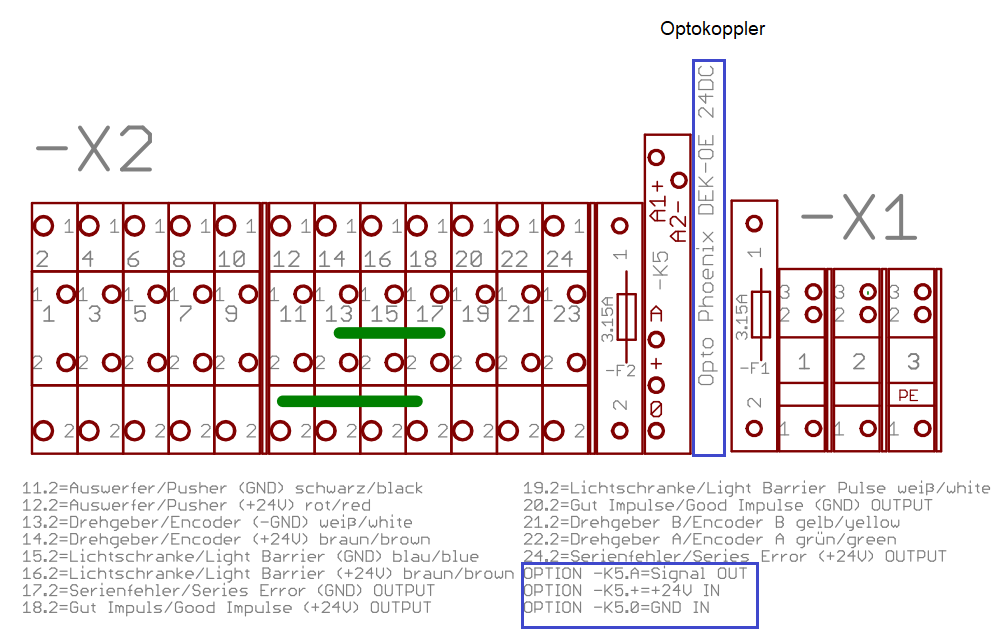

An additional optical coupler, which is mounted on the terminal strip as shown below, is used to exclude any interference between the machine controls.

Once the connection has been made according to the updated connection diagram, this ready signal is then permanently available in the customer's higher-level machine control. The filling line is only started after an internal, positive acknowledgement in the control system. This link ensures that all bottles and jars produced are subjected to a closure check.

Comments are disabled for this post.

0 comments