Reduction of product recalls and costly image damage

-

30. March 2021

-

Vacuum inspection

-

30. March 2021

-

Vacuum inspection

Reduction of product recalls and costly image damage through the new product feature ejector monitoring at INDEC 300 systems

Avoid product recalls even before the goods leave production - with the reliable vacuum inspection systems from KoCoS.

With our INDEC range of vacuum inspection systems, food manufacturers have the assurance that HACCP (Hazard Analysis & Critical Control Points) principles are met.

KoCoS vacuum inspection systems are characterised by their superior detection sensitivity and automatic rejection of defective products in the food industry.

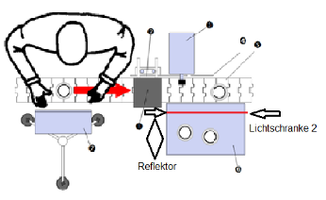

The ejector monitoring function checks whether the ejector has separated a container from the product flow that has been detected as bad. For this purpose, another light barrier is arranged parallel to the conveyor belt opposite the ejector. If the light barrier is not interrupted by the bad container within the adjustable delay after the ejector has been triggered, an error message is generated.

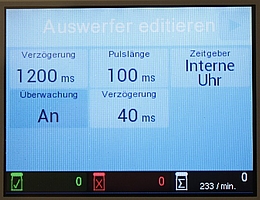

Call up the Edit Ejector screen - tap the Monitoring button, set it to ON and enter the manually determined delay. In addition to the error message, an electrical switching signal can be output via a binary output, for example to stop the production process automatically.

The costs incurred by executed recalls, such as publication of warning messages, transport back to the factory and loss of sales, are relatively easy to calculate. But the more far-reaching consequences of the action, such as the loss of brand image among supermarkets and consumers, are not so easy to foresee.

It is precisely under these conditions that smaller manufacturing companies focus on vacuum testing systems from the INDEC series to minimise the risk of product recalls. It is also a way of signalling to the authorities and their trade customers that they meet the required standards and are available for lucrative new markets.

In food manufacturing, a good reputation is particularly important. The less often improperly sealed bottles and jars reach the consumer, the better. Only in this way can manufacturers protect the image of their brand, increase sales and secure their profits.

More and more small and medium-sized enterprises are realising that the best way to achieve these goals is with an INDEC series vacuum inspection system from KoCoS.

When you integrate an INDEC vacuum inspection system into your process, you can be confident that you are meeting current HACCP requirements and that your reputation and customers are reliably protected.

Comments are disabled for this post.

0 comments