Dipl.-Ing. Jürgen Dreier, Product Manager

In order to comply with and ensure specifications, resistance measurements often have to be performed on products, such as high-current connections, during development and in the production process. To ensure product quality, the reliability of the tests is important. In addition, it is also important to perform measurement sequences quickly to keep production throughput high.

Easy configuration of a production system

For special requirements or customer-specific solutions, creating your own applications is an option. Self-created programs fulfill the own requirements optimally.

For the control and measurement of the PROMET R300/R600 resistance measuring systems, the devices are supported via an easy-to-use remote control function resp. programming interface. This interface can be used in COM/ActiveX supporting as well as in .NET environments and can be used with almost all common programming languages.

The PROMET PI programming interface is included in the scope of delivery of the PROMET R300/R600 systems. Once the programming interface is installed, PROMET PI can be used to develop programs and measurement sequences for the measuring instruments.

Program development with the PROMET PI programming interface is fast and uncomplicated. All methods and parameters are available to the user during programming and can be addressed without any problems.

Thus, the IntelliSense function provides suggestions when entering the programming code, e.g. Visual Basic for Applications (VBA) in Excel shows the available attributes and methods after entering a dot behind an object variable. The program created in this way is immediately ready to run.

PROMET R300/R600 are precision measuring instruments for determining resistances in the μΩ to mΩ range. Due to the measurement in four-wire technology and the output of high test currents up to 600 ADC, the resistance measuring instruments meet the highest accuracy requirements. Equipping the systems with three voltage measurement inputs allows parallel measurement at three measuring points at the same time.

The use of state-of-the-art power electronics and the robust design guarantee maximum reliability for stationary and mobile use in industrial environments. The operating concept and an external control via the programming interface for use in test stands make the devices of the PROMET series individual and versatile.

In most production tests, the measurement results must be compared with predefined limit values and good/bad assessments must be made. Such limit checks can be realized via programming to sort test objects according to these criteria.

Projects realized so far in C# and Visual Basic for Applications (VBA), e.g. under Excel, show the universal applicability and optimal usability.

The following system configuration shows a basic concept of a measuring system based on the PROMET R300/R600 resistance measuring instruments. Easy-to-use contacting and interfaces simplify the configuration of the test system considerably.

An important aspect is the connectivity and communication. The PROMET R300/R600 test systems offer a USB and an Ethernet interface for control. USB is widely used and easy to connect, Ethernet is suitable for distributed systems, among others.

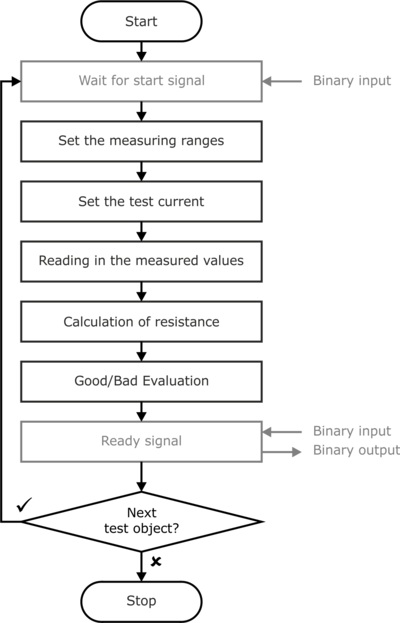

Process sequence

The following program flow chart shows a simplified sequence for testing resistors.

A program example was realized following the above procedure via Microsoft Excel and VBA macros. However, the PROMET PI can also be used in other programming environments.

The example contains the following steps, among others:

Via the button in the user interface, the connection to the device is first established via USB or Ethernet. After the measurement has been started, the system waits for a start trigger via a binary input, e.g. from the component control. Once the resistor has reached the position and the U and I contacts are attached, the controller sends the start signal to the PROMET R300/R600 to inform the system that the measurement can begin. The binary signal starts the measurement procedure. The measurement paths are now activated, the test current set and the measured values read back via the software/programming interface. The current/voltage values, the temperature channel and the binary channels are polled and displayed in the interface. A good/bad evaluation can be made via the test criteria. After the measurement is completed, the system sends a stop signal to the component controller and saves the test data on the PC.

Practical application areas

Typical applications of the resistance measurement systems are in research, development, production and in many areas where speed, precision and reliability in resistance measurement are important.

In most applications a good interaction between acquisition, processing and output is required, which the PROMET devices master perfectly.

Summary

The PROMET R300/R600 precision resistance measuring instruments are an ideal tool for characterizing components for a high current and a low resistance due to their measurement in four-wire technique and the ability to measure both current and voltage accurately.

As demonstrated in the article, the integration of the resistance measurement system into an automated application controlled by its own external software can be easily accomplished.

Using a PROMET R300/R600 resistance meter to perform such measurements simplifies the test setup, shortens programming time and enables efficient test sequences.

Postscript

The three-phase signal generator EPOS 360 can also be integrated into your own test applications in a similar form via the EPOS PI programming interface!